Fiberglass Duct Liner vs. Rubber Duct Liner: Which Is Better?

08-12-2023

Highly-populated building spaces like hotels, theaters, schools and offices can get very noisy— and very disruptive to its occupants. Duct liner insulation is a commonly-used solution to dampen unwanted noise and provide thermal insulation in these spaces.

Two of the most common duct liner options are fiberglass duct liner and elastomeric duct liner, also known as rubber duct liner. We’re breaking down the facts and differences between the two materials— including ease of application, acoustical absorption properties, thermal insulating performance, fire response, and cost— to determine which duct liner material is right for your project.

What is Acoustical Duct Liner?

Acoustical duct liner is an insulation product that is used to line the inside of HVAC ducts and air distribution system components that handle air up to 250°F (121°C). The primary function of duct liner is as an acoustical insulation, designed to reduce the transfer of acoustical energy from one location to another. The secondary function of duct liner is as a thermal insulation, designed to retard heat gain and loss with the primary goals of comfort and energy savings.

What is Fiberglass Duct Liner?

Fiberglass duct liner is made of recycled glass, sand and other rapidly renewable raw materials which are melted and spun into fibers, then formed and bonded into insulation. Fiberglass duct liner comes in blanket form as rolls, or rigid form supplied as boards. The blanket/roll form can be applied by automatic fabrication machinery, or manually applied. The rigid board products are typically manually applied.

What is Rubber Duct Liner?

Elastomeric duct liner is made of synthetic elastomers (rubber), processed to form a flexible roll or sheet, that has either an open or closed-cell structure.

Comparing Fiberglass & Elastomeric Sound Performance

Fiberglass duct liner offers a minimum Noise Reduction Coefficient (NRC) value of 0.70 for 1” thick. This means 70 percent of the unwanted sound is absorbed by the insulation.

Elastomeric duct liner offers between a 0.35 NRC (closed cell) and 0.60 NRC (open cell) for 1” thick. This means that only 35 to 60 percent of the unwanted sound is absorbed by the insulation.

Thermal Performance Differences

A misconception is that elastomeric delivers better thermal performance, when this is not the case. Fiberglass duct liner is 6 percent to 15 percent more thermally efficient, saving more energy inch to inch.

Fiberglass duct liner can achieve thermal conductivity or k-value of 0.23 for rigid plenum liner and 0.24 for flexible fiberglass duct liner. Compare that to elastomeric which can provide a minimum K-value of only 0.245 in closed cell product and 0.28 in open-cell. A lower k-value means better thermal control.

Durability— Does Fiberglass Shed Fiber?

Both materials go through the same testing process to determine fiber erosion, measured as a velocity rating in which the duct liner must not shed fiber after facing extremely high-speed air stream velocity.

Most fiberglass duct liner products are rated to serve at 6,000 feet per minute (FPM) maximum velocity (tested at 15,000 FPM). Elastomeric duct liner products are rated to serve at 4,000 FPM maximum velocity. This far outperforms the typical range for commercial HVAC systems of 1,000- 2,000 FPM.

Indoor Air Quality- VOC & Formaldehyde emissions

Fiberglass and elastomeric cellular foam duct liners are subject to the same testing and requirements when it comes to formaldehyde and VOC emissions. Knauf duct liner products are UL Environment validated as formaldehyde-free and are GREENGUARD and GREENGUARD Gold certified for emissions.

Elastomeric insulation materials are rated similarly.

Ease of Installation

Because elastomeric cellular foam is made using synthetic rubber, it can be substantially more difficult to install. Fiberglass duct liner pins, glues, and cuts more easily.

Fiberglass can be run through automated duct fabrication equipment. Many times, elastomeric duct liner will not process effectively in automated machinery, restricting application to manual processes, significantly increasing time to fabricate.

Fiberglass duct liner allows adhesive to dry faster and completely, allowing the duct to be installed sooner. Special adhesives may be required with elastomeric cellular foam, creating difficulty with gluing equipment and speed of installation.

Differences in Fire Safety

Being made of glass, fiberglass duct liner is naturally resistant to fire and is Class A rated 25/50 without the need of added flame retardants. Fiberglass meets the requirements of ASTM C1071, including fire response characteristics.

Elastomeric insulation is made of synthetic chemical polymers which are naturally combustible. To protect against fire hazards, elastomeric duct liner is treated with fire retardant chemicals such as antimony oxide or aluminum trihydrate.

Some elastomeric duct liners emit hydrogen cyanide gas when in fire conditions. This gas mixes with water to create hydrochloric acid effluent as a result of firefighting practices.

Moisture Properties

Both fiberglass duct liner and elastomeric are tested for the ability to resist moisture transport and retention. There is a misconception that fiberglass will hold and carry water and that elastomeric duct liner will not. In fact, open-cell elastomeric foam is a material that is technically designated as “sponge rubber,” a highly-absorptive product meant to hold water within its cellular structure.

The allowable water absorption value of open-cell elastomeric duct liner is 4 percent gain by volume, and closed cell is 0.2 percent for the same property. This demonstrates that elastomeric rubber is not immune to this characteristic.

Fiberglass duct liner standards require no more than a 3 percent weight gain by water vapor sorption testing.

Mold, Mildew, and Bacteria Resistance

Both fiberglass duct liner and elastomeric cellular foam are tested for the ability to resist fungi growth, using the same standard test methods (ASTM C1338, ASTM G21 and ASTM G22). Both materials are required to exhibit no ability to support microbiological (mold, mildew and bacteria) growth when using these tests. Knauf duct liner is also tested to UL2824 which is a special standard that no other fiberglass or elastomeric manufacturer tests to.

Packaging & Waste

Fiberglass duct liner is packed under compression, while rubber cannot be compressed. This allows fiberglass manufacturers to pack more product into each roll. This minimizes the space required in warehouses and trucks compared to elastomeric duct liner.

Knauf duct liner requires 50 percent fewer rolls of material vs. elastomeric cellular foam, when comparing 1” thick packaged product. Duct fabricators can spend less time installing as it requires fewer rolls to handle when loading duct liner into equipment. Longer rolls also reduce scrap, saving on waste material — which can make the job more efficient.

Knauf duct liner is packaged in polyethylene bags and sleeves which dispose of easily including being recyclable. Most forms of elastomeric cellular foam are packaged in large, bulky corrugated cartons that require extra labor and disposal space in waste containers. Minimized and recyclable packaging is becoming more important to sustainable construction projects.

What is the Cost Difference Between Elastomeric and Fiberglass Duct Liner?

These two products are far different in price. Elastomeric is 5-6x the cost of fiberglass and takes up to twice as long to install. To put that in perspective, an 800-room hotel in a major city was estimated to need to spend approximately $500,000 more to put in elastomeric instead of fiberglass.

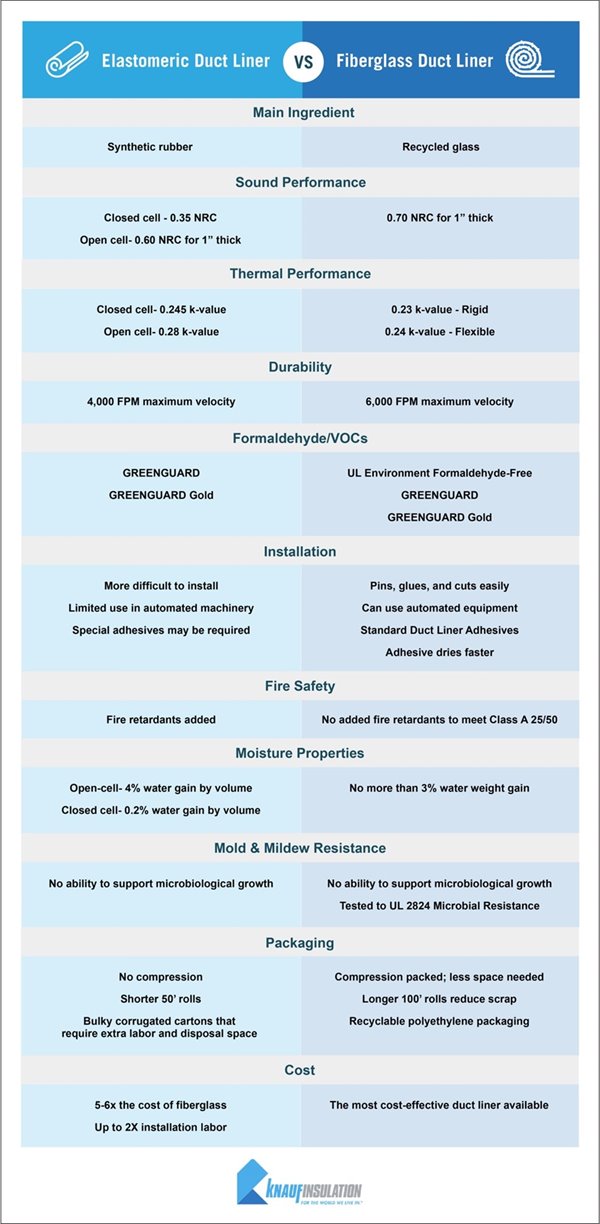

Side-By-Side Comparison

The Best Duct Lining Insulation Choice

Fiberglass duct liner provides more acoustical control, similar thermal control, and a far lower cost than elastomeric duct liner. With its ease of installation, superior all-around performance, and significant cost advantage, it’s no wonder fiberglass duct liner is the choice of most HVAC air distribution system designers and installers.

Sources

- NAIMA Fibrous Glass Duct Liner Standard- Design, Fabrication and Installation Guide

- SMACNA HVAC Duct Construction Standards

- NFPA 90A

- ASHRAE Handbook of Fundamentals

- ASTM C1071-19 Standard Specification for Fibrous Glass Duct Lining Insulation